The basic structure of power cables

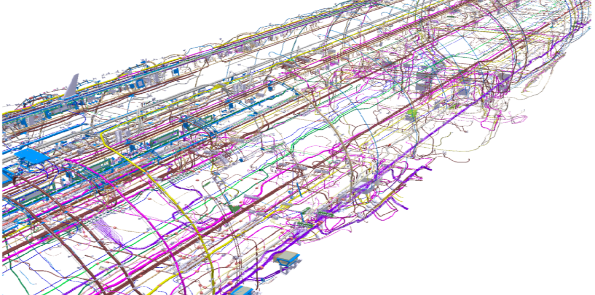

Power cable refers to the metal wire core insulation wrapped around the package, with shielding material shielding, sealing, to transmit electrical energy special wire. Power cable mainly by the core, the conductor shield, insulation, insulation shielding, metal shield, armor layer, outer jacket

1. core

(1) the role is used to transmit electrical energy, commonly used materials for copper, aluminum.

(2) core structure: to take a number of filament twisted into a bundle, after the mold through the compression, so that the compression factor from 0.73 to 0.9 or more, is conducive to crimping connection.

(3) cable conductor resistance: the conductor itself has a resistance, through the current will heat, the temperature rise is the key factor limiting the cable carrying capacity. We hope that the conductor's resistance is as small as possible.

2. Conductor shield

(1) conductor shield is squeezed in the cable conductor on the non-metallic layer, and the conductor equipotential, volume resistivity of 100 ~ 1000Ω? M. And equipotential potential.

(2) General conditions 3kV and below low-voltage cable without conductor shield, 6kV and above the high-voltage cables must have a conductive shield.

(3) the main role of the conductor shield: the elimination of the conductor surface potholes uneven; eliminate the tip of the conductor surface effect; eliminate the conductor and insulation between the pores; so that the conductor and insulation between the close contact; improve the conductor around the electric field distribution; For the cross-linked cable conductor shield also has to suppress the growth of thermal tree and thermal shielding effect.

3.Insulation

(1) cable main insulation with a specific function to withstand the system voltage, the cable life cycle, to withstand long-term rated voltage and system failure when the over-voltage, lightning impulse voltage to ensure that the working heat does not occur in the relative or Phase breakage short circuit. So the main insulation material is the key to the quality of the cable.

(2) Cross-linked polyethylene is a good insulating material, now widely used, its color is green and white translucent. Low dielectric loss tangent; chemical stability; good heat resistance, long-term allowable operating temperature of 90 ℃; high dielectric loss; high resistance; Good mechanical properties, easy processing and process.

4. Insulation shield

(1) Insulation shield is extruded in the main insulation of the cable on the non-metallic layer, the material is also cross-linked material, with semi-conductive properties, volume resistivity of 500 ~ 1000Ω/ M. And ground protection equipotential.

(2) the general situation 3kV and below low-voltage cable without insulation shield, 6kV and above the high-voltage cables must have insulation shield.

(3) the role of insulation shield: the main cable insulation and grounding metal shield between the transition, so that there is close contact to eliminate the insulation and grounding between the conductor; to eliminate the tip of the surface of the copper surface effect; improve the insulation surface Peripheral electric field distribution.

(4) Insulation shielding According to the process is divided into strippable and non-peelable type, the general medium voltage cable, 35kV and below the use of strippable, good peelable insulation shield with good adhesion, no semi-conductive particles after stripping residue. 110kV and above with non-peelable type. The combination of non-peelable shields and main insulation is more tight and the construction process is required.

5. Metal shield

(1) metal shield wrapped in the insulation shield, the metal shield is generally used copper or copper wire, which is limited to the electric field inside the cable to protect the personal safety of the key structure. It is also a ground shield that protects the cable from external electrical interference.

(2) metal sheath of the material and structure generally use corrugated aluminum sheath; corrugated copper jacket; corrugated stainless steel sheath; lead jacket and so on. In addition there is a composite sheath, is used in aluminum foil affixed to the PVC, PE jacket within the structure, the use of more products in Europe and the United States.

6. Armored layer

(1) in the lining layer wrapped around the metal armor layer, the general use of double galvanized steel tape armor. Its role is to protect the internal cable to prevent the construction, operation of the mechanical force on the cable damage. Also has the role of grounding protection.

(2) armored layer has a variety of structures, such as steel armor, stainless steel armor, non-metallic armor, etc., for a special cable structure.

7. outer jacket

(1) This is the outermost protection of the cable, the general use of polyvinyl chloride (PVC) polyethylene (PE), are insulating materials, the use of extrusion molding. In accordance with technical requirements, the general use of flame retardant PVC (PVC). Adapt to winter cold and hot summer requirements, no cracking, no softening.

(2) the main role of the outer jacket is sealed to prevent moisture intrusion, to protect the armor layer from corrosion, to prevent the cable failure caused by fire expansion.

(3) in the outer jacket is also printed on the characteristics of cable information, such as specifications, models, production year, the factory, continuous meter length and so on.

The above is a brief introduction to the basic structure of the power cable, learn more about the power cable content, please pay attention to kingsignal official website.