Power cable construction should pay attention to the problem

The quality, safety and reliability of the power supply system are not only related to the quality of the wire and cable itself, but also to the construction quality of the power cable accessories and lines. Here to tell you about the construction of power cable should pay attention to the problem

1. Large current power cable caused by the eddy current problem

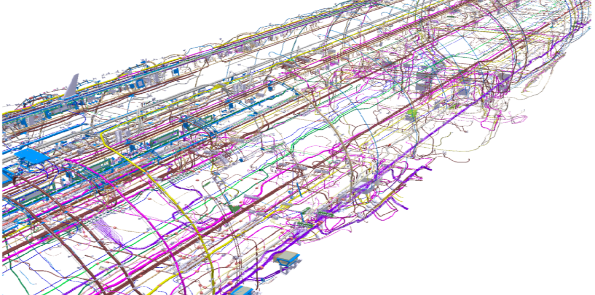

Power cable in the construction, there are steel stent, there are steel protection tube, there are cable and overhead laying, usually in the power cable around the formation of steel (iron) closed loop, are likely to form a vortex, Especially in high-current power cable systems, the greater the vortex. In the construction of power cable, we must take measures to make the cable around the formation of steel (iron) closed circuit to prevent the cable caused by eddy current phenomenon.

2. mechanical damage caused by the turn of the power cable

As the power cable larger diameter, transport, laying more difficult, power cable on the turning radius of the requirements are more stringent. Power cable in the construction, if the turning angle is too large, may cause damage to the internal mechanical damage, and mechanical damage due to cable insulation strength decreased until the failure, the construction found a cable head failure, cable head production, the three cables Head length consistent with the equipment connected due to terrain restrictions, the middle of the cable head is long and become arched, the cable head damaged damage. After taking measures to connect the equipment in the appropriate shortening of the length of the cable head connection, so that three-phase cable head are not subject to external force, the practice proved good results. It can be seen, the cable construction process, as far as possible to reduce the cable by the torque in the cable turn and leave the cable, so that the cable in the natural bending, to prevent internal mechanical damage.

3.power cable

Operation experience shows that most of the middle and low voltage power cable faults are cable intermediate joints and terminal failures, while the middle joints and terminal failures are mostly due to poor sealing, moisture intrusion caused by dielectric strength decreased, while the low voltage power cable The use of dendritic power supply network, the number of cable terminals more, so the cable terminal and the middle of the plug seal is to ensure the safe and reliable operation of the cable one of the important measures.

4. Medium and low voltage power cable grounding problems

In the public, the low-voltage power cable network, because the three-phase load is not equal, so if the use of metal sheath of the cable, you must consider the metal sheath of the grounding problem, and to ensure that any point in the metal sheath The normal induced voltage must not exceed 100V. We believe that in the middle and low voltage cable network, all cable joints should be set at the ground (net), and the metal sheath is reliably grounded.

The above is the power cable in the construction process should pay attention to the brief introduction, to learn more about the power cable content, please pay attention to kingsignal official website.