Advantages and characteristics of optical cable in industrial applications

For the development of Ethernet believe that we can understand that it has spread from the traditional office environment to various fields, which contains the factory and building automation and so on. Although the copper cable is still commonly used in Ethernet, but the optical cable because of its long distance capability, and the advantages of electrical isolation interface, in industrial applications to achieve more and more success.

Loss or corruption of a packet may cause any network to fail, but this is a problem for the industrial bus. These buses have some level of synchronization to maintain strict control and accuracy. Most industrial buses use specific time synchronization packets to synchronize through continuous and uninterrupted communication. When a packet is not reached, it not only affects the node synchronization down to the link, but also causes additional packet transmission, resulting in packet loss or corruption.

1. Radiation / Conduction Emission

An industrial environment can include a variety of electromagnetic radiation sources. The motor and the mechanical equipment can produce parasitic signals coupled to the copper and cause the packet to fail. These signals can interfere with the steady flow of information on which the industrial bus lives. The worst case scenario is that the cable may even become a path that causes the high energy level to reach the PHY, resulting in loss or even damage to the link.

The optical cable can solve some of these problems. It does not make the electromagnetic properties of the radiation in the copper. To transmit light through plastic or glass. Because the existence of copper, will not produce a magnetic field, and optical cable is not susceptible to power surge and industrial environment, the impact of energy transient pulse.

2. Electrical isolation

In the fiber optic network, there is no electrical connection between the nodes. Therefore, the network nodes can not form different common-mode voltage levels or common-mode transients on the cable, which may affect the packet. If the high voltage will cause safety problems, may also need fiber.

When using copper, the Ethernet network node is usually a transformer coupled to the cable. Although this does have isolation, there is still an electrical connection between the network nodes. Optical cable Add another isolation layer by eliminating any direct electrical path.

3.Distance

The Institute of Electrical and Electronics Engineers (IEEE) 802.3 standard defines standard Ethernet as a 100 meter copper cable. Although the distance is sufficient for most applications, there is a basic limit on the distance that the physical copper medium can support in cases where the packet is not wrong.

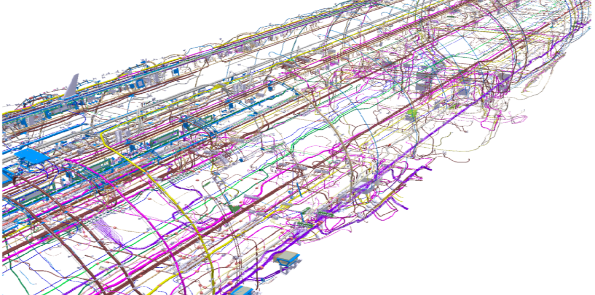

4. Optical fiber in industrial applications

Fiber optic communications support far more distance. Among them, the copper network node spacing of tens of meters, and fiber optic network nodes can be separated by hundreds of meters or several kilometers. Therefore, in industrial applications, the network can be bridged between buildings or between substations connecting high-power power grids.

The above is a brief introduction to the advantages and characteristics of optical cable in industrial applications. To learn more about the content of the optical cable, please pay attention to the kingsignal website.