Submarine optical cable laying and its fault handling

The submarine communication cable is a wire wrapped with insulating material, which is laid on the sea floor to realize the telecommunication transmission between countries. The first submarine communications cable provided telegraphic communications, and later began to introduce telephone communications and Internet communications, while modern optical cable also used fiber technology, so called the sea optical cable.

How to lay the sea cable

In simple terms, the laying of the cable is the optical cable on the submarine optical cable laying the ship, and then the boat slowly started while the optical cable tiled into the bottom of the sea.

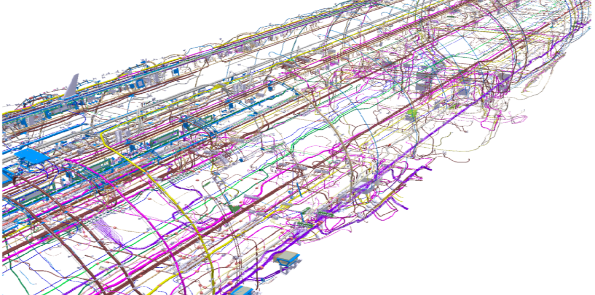

Specifically, the optical cable laying consists mainly of optical cable routing exploration, optical cable laying and blasting protection in three stages. The optical cable laying is usually done by digging the submarine cable burying machine, which is somewhat like the plow used when plowing, by the sea cable cable laying the ship towing forward and making various instructions through the work of the optical cable. The bottom of a few rows of water holes, operation, each hole at the same time to the sea jet out of the high pressure water column, the sea sediment open, the formation of optical cable groove. And the upper part of the device has a cable hole for guiding the optical cable (optical cable) to the bottom of the optical cable.

In the past, often by the sea to make sand naturally covered in the ditch above, to save the time to buried cable. And now usually will be equipped with high-pressure water pump underwater robot rushed a ditch and then put into the soil.

Optical cable is designed to control the speed of the cable cable and to lay the tension by controlling the speed of the ship, and to avoid damage to the optical cable due to the small bending radius or too much tension. When the deep sea is laid, the optical cable laying out the ship to release the optical cable, using the underwater monitor, the underwater remote control vehicle continuously to monitor and adjust, to control the speed of the ship, the direction and the speed of the laying of the optical cable to bypass the bump Uneven place and rock to avoid damage.

How to repair submarine optical cable

Submarine optical cable often fails, sometimes from ships, sharks and other inadvertently destroyed, sometimes the enemy's deliberate destruction, more often is the earthquake caused by the problem. For example, in 2006 by the Taiwan earthquake, a number of international submarine communications optical cable disruption, resulting in domestic Internet users can not properly access foreign sites. Similarly, in 2011, by the impact of the earthquake in Japan, a number of routes through the Japanese sea off the sea cable failure, and then many Chinese users found unable to log on the US site.

Compared with the laying of optical cable, repair optical cable difficult to increase, because from a few hundred meters or even a few kilometers from the seabed to find a diameter of less than 10 cm problem optical cable, just like a needle in a haystack, and repair Continued the difficulty of renewal is also very large.

Usually, the general sea cable cable fault will be processed in five steps. First, use the spread spectrum time domain reflectometer to locate the approximate fault location. After that, find the exact location of the damaged cable cable through the dive robot, cut off the fault location, and drag the remaining ends back to the repair ship for repair. Next, use the spare submarine optical cable to connect the two broken points of the damaged optical cable, and then put it back to the sea.

The above is a brief description of the laying of the sea cable and its fault handling, to learn more about the contents of the optical cable, please pay attention to kingsignal official website