Causes and Countermeasures of Power Cable Line Fault

Power cables are used to transmit and distribute electrical energy cables, power cables commonly used in urban underground power grids, power plants lead lines, industrial and mining enterprises within the power supply and across the river underwater transmission lines.

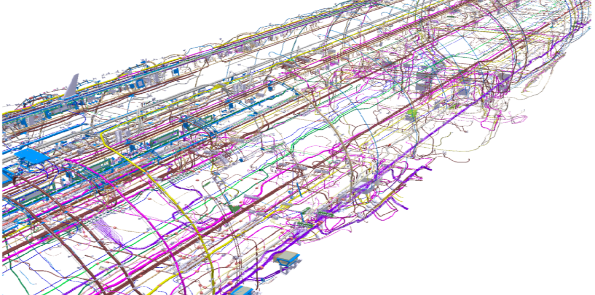

Power cable basic structure

The basic structure of the power cable consists of core (conductor), insulation layer, shielding layer and protective layer of four parts.

1. core

The core is the conductive part of the power cable, used to transport power, is the main part of the power cable.

2.Insulation

Insulation layer is the core and the earth and the different phase of the core between the electrical isolation from each other to ensure that power transmission, power cable structure is an indispensable part.

3. Shield

15KV and above power cables generally have a conductor shield and insulation shield.

4. Protective layer

The role of the protective layer is to protect the power cable from external impurities and moisture intrusion, and to prevent external damage to the power cable.

Causes and Countermeasures of Power Cable Line Fault

1. external damage

In the custody, transportation, laying and operation of the cable may be subject to external damage, in particular, has been running the buried cable, in other works of the ground construction vulnerable to damage. Such accidents often account for 50% of cable accidents. In order to avoid such accidents, in addition to strengthening the cable storage, transportation, laying and other aspects of the quality of work, the more important is the strict implementation of the system.

2. Protective layer corrosion

Underground stray current electrochemical corrosion or non-neutral soil chemical corrosion of the protective layer failure, loss of protection against insulation. The solution is to install the drainage equipment in the stray current-intensive area. When the local soil on the cable line contains chemical substances that damage the cable lead pack, the cable should be installed in the tube and the neutral soil is used as the cable for the cable And cover, but also in the cable coated with asphalt.

3. Overvoltage, overload operation

Improper selection of cable voltage, in the operation of a sudden high-pressure fleeing or long-term overload, are likely to damage the cable insulation strength, the cable breakdown. This need to strengthen the inspection inspection, improve the operating conditions to solve in a timely manner.

4. Outdoor terminal head soaked

Due to poor construction, insulation is not filled, causing the terminal head soaked, the final explosion. So to strictly implement the construction process, a serious acceptance; to strengthen inspection and timely maintenance. Terminal head oil spill, damage the sealing structure, so that the end of the cable immersed in the loss of dry, increased thermal resistance, insulation accelerated aging, easy to absorb moisture, resulting in thermal breakdown. Found that the terminal head of oil leakage should strengthen the inspection, serious power should be redo.

The above is a brief introduction to the power cable, learn more about the power cable content, please pay attention to kingsignal official website.